Origin of Vacuum glass

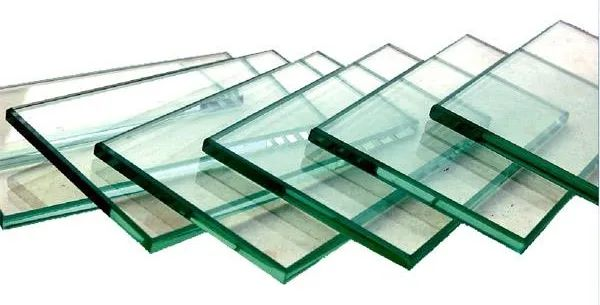

When it comes to vacuum glass, we have to mention the Devar vessel, which is commonly used in the home as a kind of devar vessel. What does vacuum glass have to do with devar vessel? First let's look at the principle of the devar vessel. In 1892 James Devar, a professor at the University of Cambridge, invented the devar vessel, a double-glazed container with two layers of glass bile wall coated with silver, and then pumped the air between the two layers of glass to create a vacuum. Because vacuum prevents convection and conduction of heat dissipation, the silver coating prevents radiation from dissipating heat, so the devar vessel has a good insulation effect. According to this, he summed up two basic principles of vacuum insulation: eliminating most of the heat convection and thermal conduction through high vacuum; Reduce thermal radiation with a high-reflective coating. This becomes the basic principle of high insulation performance of vacuum glass.

Pic1: Vacuum Glasses

Along the road opened by Prof.Dewar, in 1913 Mr. A. Zoller first proposed the concept of vacuum glass. Since then, since the 1980s, the development of vacuum glass has become more active. Vacuum glass is two pieces of flat glass around the closed, its clearance into a vacuum and seal the vents. at least one of the two pieces is low-radiation glass (Low-E glass), so as to minimize the heat lost through the vacuum glass conduction, convection and radiation. In 1998, China's vacuum glass began to develop, but it was not until 2008, when China set the world's first vacuum glass industry standard, the vacuum glass approached to the Chinese people, and successfully got applied to the building's curtain wall glass and windows.

Pic2

Principles and Advantages

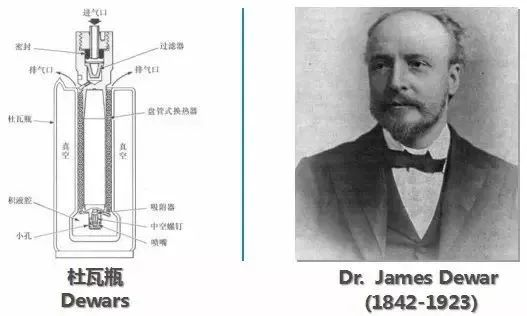

Vacuum glass consists of low-Emission glass (Low-E glass), high vacuum inner cavity, high-efficiency aspirator, upholder, pump port, etc. After the upper and lower two pieces of glass are sealed with brazing, the glass laminated is vacuumed from the pumping port by a pumping station, and the gas outlet is sealed after the expected vacuum rate has been achieved. Because of the large glass area and thin thickness, the two pieces of glass need a cloth upholder matrix to support, to prevent damage to the glass due to atmospheric pressure. Small leaks are inevitable from brazing seams and vents between the glass, so to maintain the vacuum rate of the glass laminate, efficient aspirators need to be placed to absorb the leaking gas. Vacuum glass is an important member of energy-saving glass, with the following two most prominent advantages.

Pic 3:Vacuum structure

Advantage 1: Non-condensate

The vacuum layer in the middle of the vacuum glass reduces the heat transfer of the gas and convection to such a low level that it is negligible. As a result, vacuum glass has better thermal insulation than hollow glass. The technical parameters of the excellent insulation performance of vacuum glass are the heat transfer coefficient U value, which is W/(m2 *K). Because there is no air in the vacuum layer of vacuum glass, no water vapor molecules, sealing is very tight, thermal resistance is large, in winter no condensation phenomenon happened.

Advantage 2: Sound insulation and noise reduction

Sound travel requires a medium, solid, liquid or gas. But in a vacuum environment without medium, sound can not be transmitted, so the vacuum layer of vacuum glass can effectively block the travel of sound. Vacuum glass, especially at low to medium frequencies, exhibits good sound insulation and is suitable for use in laboratories, recording studios, etc. where windows are not required and noise sensitivity is not required.

Conclusion:

Vacuum glass is a new type of glass deep processing products, is the cutting-edge products with independent intellectual property rights in China's glass industry . Its research and development promotion is in line with China's policy to encourage independent innovation, but also in line with the state vigorously advocated energy conservation and "double carbon" policy, with good development potential and prospects. Vacuum is an important process of vacuum glass manufacturing, because the vacuum rate of the laminate is closely related to the insulation performance of glass, vacuum pumping system is mostly using turbomolecular pumping station, a unit can pump a group of glass at the same time. With the continuous improvement and innovation of vacuum glass manufacturing process in the past two years, the market demand for product quality and performance is getting higher and higher, magnetically levitated molecular pumps gradually entered the field. KYKY molecular pumps and other products in the vacuum glass industry has many years of successful application experience, and gained the reputation and trust. In the future, KYKY will continue to serve the industry segmentation and to provide customers with better products and services.

Post time: Aug-19-2021