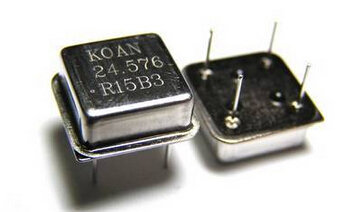

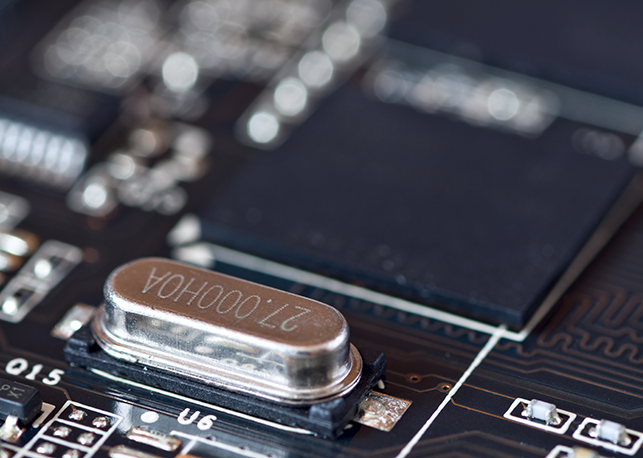

Crystal oscillator is commonly used clock components in circuits, its main role is to provide the reference frequency to graphics cards, network cards, motherboard and other parts of the components, widely used in information devices, mobile terminals, smart wear, Internet of Things and other fields. The normal operation of electronic circuits depends on the regular, stable “clock signal”, under normal operating conditions, the absolute accuracy of ordinary crystal frequency can reach 50 per million.

The main functional material of quartz is crystal, a hexagonal conical crystal with a chemical composition of silicon dioxide (SiO2).

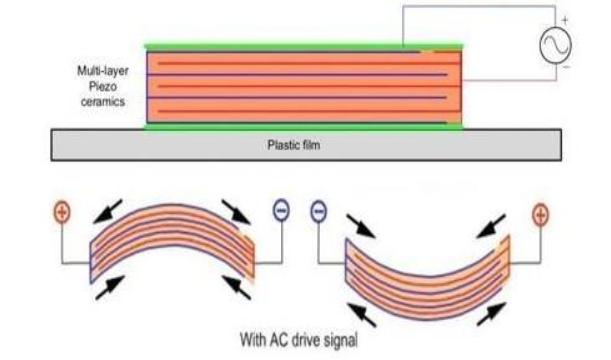

Quartz is the raw material for resonators because of its piezoelectric effects of positive (mechanical energy→ electricity), inverse (electrical → mechanical energy). If pressure is applied along the shafts or mechanical shafts of quartz wafers to deform the wafers, the two surfaces perpendicular to those axes generate an electric charge, a phenomenon known as a positive piezoelectric effect. If an electric field is applied on both surfaces of a quartz crystal, the wafer extends or compresses in the direction of the shaft and the mechanical axis, a phenomenon known as the counterpressure effect. Based on this characteristic, when the quartz crystal is placed in an alternating electric field, the volume of the crystal is periodically compressed or stretched, forming the mechanical vibration of the crystal. When the frequency of the alternation field is equal to the inherent mechanical resonance frequency of the wafer, the mechanical vibration amplitude of the wafer is the largest, resulting in resonance.

In the production , the four processes of silver plating, Tuning, bonding and testing will be complemented in vacuum condition as below.

Silver plating machine

In the process of manufacturing quartz crystal elements, double-sided silver plating is required on the already cut substrate to form a double-sided electrode. Over the past few years, high vacuum by silver machines generated by diffusion pumps. Due to quality and energy efficiency requirements, turbomolecular pump are used gradually to replace diffusion pumps in the industry.

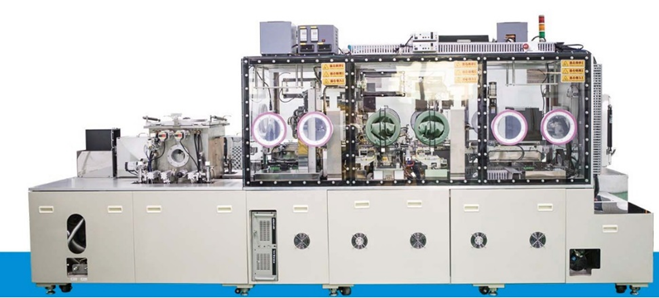

Tuning machine

Ion etching method is adopted to adjust the thickness of the wafer surface electrode, so that the crystal resonator frequency reaches the target oscillation frequency. The equipment equipped with a double conveyor boat is available for 1280 crystal oscillation elements, of function of real-time monitoring crystal oscillation frequency, can handle 64 crystal vibration elements at the same time. The vacuum chamber of the fine-tuning machine is divided into the preparation chamber and the fine-tuning chamber. When the equipment is turned on, the vacuum degree of the preparation chamber will be reduced from atmospheric pressure to dozens of Pa, the vacuum degree of the fine-tuning chamber will eventually be reduced to 10-3 to 10-4 Pa. Generally, Molecular pumps are used to generate the high vacuum in the fine-tuning chamber .

Welding machine

The welding process is to seal the upper cover with the base to ensure that the aging rate of the product meets the requirements. Wherein passive crystal can be directly filled with nitrogen gas to seal, while active crystal needs to be added vibration chip before sealing. In the vacuum annealing process part of the sealing machine, a high vacuum is obtained by using a molecular pump.

In recent years, with the rapid development of downstream applications such as 5G, automotive electronics and mobile terminals, the crystal industry has ushered in new opportunities. As a vacuum industry solutions experts, KYKY has a wealth of experience in the field of crystal oscillator, has provided a full range of vacuum products and customized solutions. In the future, KYKY will continue to dig deep into the industry segments, adhering to provide customers with better quality products and services.

Post time: May-14-2021